Blog

Best Laser For Starting A Business | 10 Things ...

One of the most common questions I get regarding laser machines is why I chose Epilog and if I were to do it over again, would I stick with Epilog....

Best Laser For Starting A Business | 10 Things ...

One of the most common questions I get regarding laser machines is why I chose Epilog and if I were to do it over again, would I stick with Epilog....

How to Price Your Work

One of the biggest challenges for makers is what to charge for your work. I remember when I decided that I wanted to try selling the items that I was...

How to Price Your Work

One of the biggest challenges for makers is what to charge for your work. I remember when I decided that I wanted to try selling the items that I was...

How to Make Your Product Packaging Stand Out!

I love making custom signs. When it comes to packaging them, let's just say that I had a lot of room for improvement. With my latest changes, I finally feel...

How to Make Your Product Packaging Stand Out!

I love making custom signs. When it comes to packaging them, let's just say that I had a lot of room for improvement. With my latest changes, I finally feel...

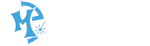

Custom Art Mirrors | Collaboration with Pretty ...

A local artist in Las Vegas named Adam reached out to me to see if I could cut mirror acrylic material to create custom pieces of art. Working with mirror...

Custom Art Mirrors | Collaboration with Pretty ...

A local artist in Las Vegas named Adam reached out to me to see if I could cut mirror acrylic material to create custom pieces of art. Working with mirror...

Making a Custom Card With a Laser

One of the best benefits to the RF style laser is the ability to adjust the frequency of the laser pulse to achieve different effects. In this project, I wanted...

Making a Custom Card With a Laser

One of the best benefits to the RF style laser is the ability to adjust the frequency of the laser pulse to achieve different effects. In this project, I wanted...

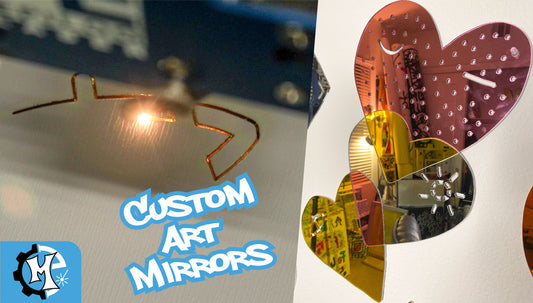

Maximizing Laser Production and Your Profits

One of the most common questions I get is, how do I charge for my work and how do I maximize my production. The main driver for this is going...

Maximizing Laser Production and Your Profits

One of the most common questions I get is, how do I charge for my work and how do I maximize my production. The main driver for this is going...